The Role of CFD Simulation in Centrifugal Pump Design

Centrifugal pumps are indispensable in various industries, including water treatment, oil and gas, and manufacturing. Ensuring their efficiency and reliability is critical to minimizing operational costs and maximizing performance. Computational Fluid Dynamics (CFD) simulation is a powerful tool that enables engineers to design, analyze, and validate centrifugal pumps with precision and confidence.

At CFD Vision, we offer cutting-edge CFD simulation services tailored to pump simulation and centrifugal pump validation, ensuring that each design meets the highest standards of efficiency and durability.

Case Study: Designing a High-Performance Centrifugal Pump

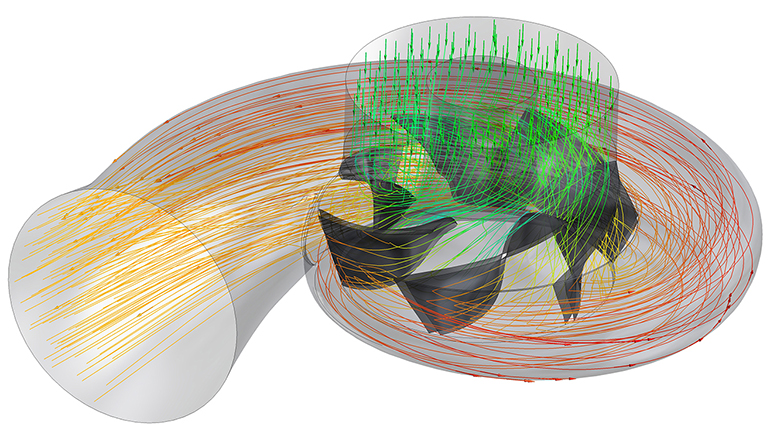

In one of our recent projects, we developed a centrifugal pump designed to achieve a static head of 60 meters while delivering a water flow rate of 2200 m³/hr. Using CFD simulation, we were able to investigate the pump’s internal flow characteristics, optimize its performance, and validate its design before manufacturing.

Key steps in this pump simulation project included:

- Creating a 3D Model

A precise 3D model of the centrifugal pump was generated to replicate real-world conditions accurately. This model served as the foundation for CFD analysis, capturing details of the impeller, volute, and other critical components. - Conducting Flow Simulation

Using advanced CFD tools, we simulated the internal flow of water through the pump. This provided insights into velocity profiles, pressure distribution, and turbulence patterns. - Validating Performance

The simulation results were analyzed to ensure the pump could meet the desired head and flow rate. This centrifugal pump validation process identified potential design improvements to enhance performance and efficiency. - Optimizing Design Features

By modifying blade angles and optimizing the volute shape, we minimized energy losses and improved the overall performance of the pump.

Benefits of CFD Simulation in Pump Design

CFD simulation offers numerous advantages in the design and validation of centrifugal pumps:

- Enhanced Efficiency: Pump simulation identifies areas of energy loss, allowing for targeted improvements that boost efficiency.

- Performance Validation: Centrifugal pump validation ensures that designs meet operational requirements under real-world conditions.

- Cost Savings: Early identification of design flaws reduces the need for expensive physical prototypes and testing.

- Detailed Insights: CFD provides a deep understanding of flow patterns, pressure distributions, and turbulence zones, helping engineers make informed decisions.

For industries relying on centrifugal pumps, incorporating CFD simulation into the design process is a game-changer, ensuring pumps perform optimally and reliably over their lifespan.

Advanced CFD Consulting for Pump Simulation

At CFD Vision, we specialize in providing CFD consulting and analysis services that address the complex challenges of pump design. Our expertise in pump simulation and centrifugal pump validation enables us to deliver solutions that meet and exceed client expectations.

Our services include:

- Comprehensive CFD simulation to analyze pump performance under various operating conditions.

- Detailed validation processes to ensure compliance with performance requirements.

- Flow simulation and optimization to enhance efficiency and reliability.

Whether you need to design a new pump or validate an existing one, our CFD consulting services are tailored to your unique needs.

Common Issues Resolved by CFD in Pump Design

Using CFD simulation, we help clients overcome challenges such as:

- Turbulence and Cavitation: Identifying and mitigating areas prone to turbulence and cavitation, which can reduce efficiency and damage pump components.

- Pressure Losses: Analyzing pressure distribution to minimize losses and improve energy transfer within the pump.

- Flow Imbalances: Ensuring uniform flow distribution across pump components for consistent performance.

Why Choose CFD Vision for CFD Simulation of Pumps

As industry leaders in computational fluid dynamics, we bring years of experience and cutting-edge technology to each project. Our team is dedicated to helping you achieve the highest levels of performance and reliability for your centrifugal pumps.

Contact CFD Vision today to learn more about our CFD simulation services, including pump simulation and centrifugal pump validation. Let us help you design and validate pumps that set new benchmarks in efficiency and reliability.

Beyond pumps, CFD Vision applies the same methods to a wide range of systems. Explore our product design services to see how smart simulation can improve efficiency and reliability across your projects.