CFD Vision – Your Partner in Product Development and Design Consulting

In today’s fast-moving industrial world, companies need efficient and intelligent design processes to stay competitive. From lowering production costs to accelerating innovation, advanced engineering and simulation tools are at the heart of modern product development.

At CFD Vision, our team of Product Development Consultants and Product Design Consultants combines CFD simulation expertise with CAD services and 3D modeling to help clients create smarter, more reliable products. We transform complex challenges into innovative, optimized, and cost-effective design solutions that enhance performance and reduce risk.

By leveraging our expertise in engineering simulation, innovative design, and equipment design, we help clients turn complex challenges into reliable, efficient, and cost-effective solutions.

Why Simulation is Essential in Modern Product Development

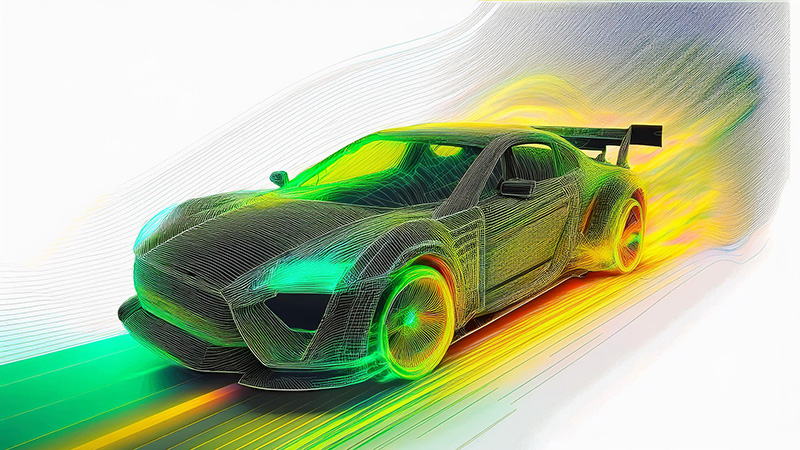

Traditional trial-and-error approaches to product development can be time-consuming, expensive, and often prone to errors. With advanced computational tools like CFD simulation, thermal analysis, and mechanical modeling, designers can visualize and test fluid flow, heat transfer, and structural behavior before any physical prototype is built.

Key benefits of using simulation in product design services and engineering development include::

- Reduced prototyping costs

- Shorter development cycles

- Improved product performance and safety

- Accurate predictions of fluid, thermal, and mechanical behavior

- Informed decision-making for design iterations

Designing Experimental Facilities with CFD Insights

Laboratories, universities, and research institutions often require experimental facilities such as wind tunnels, heat transfer rigs, and fluid flow test benches. As Industrial Design Consultants, CFD Vision applies engineering simulation consulting to ensure each system performs reliably and efficiently.

For example, designing a small-scale wind tunnel for aerodynamic testing requires precise airflow control. Using CFD simulation, we can predict turbulence, velocity profiles, and pressure distribution, allowing engineers to refine duct geometries and fan placement. This reduces the cost of multiple physical prototypes while improving experimental accuracy.

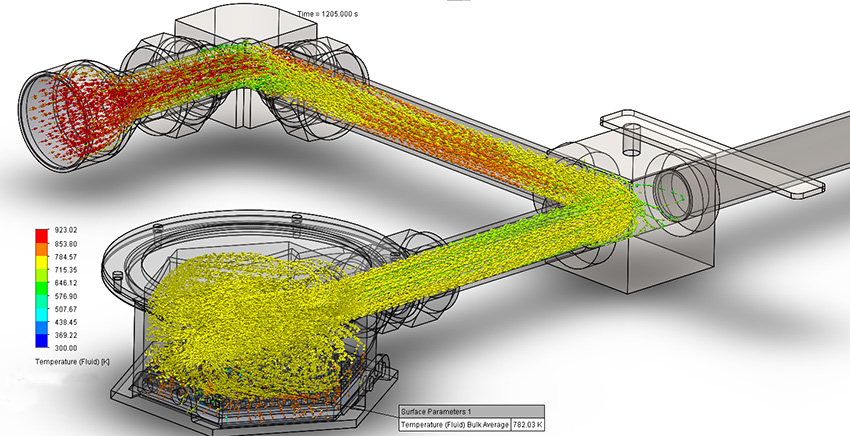

Similarly, heat transfer rigs and fluid flow benches benefit from simulation-driven design. By modeling thermal gradients and flow patterns, engineers can optimize sensor placement, ensure uniform heating or cooling, and improve overall measurement reliability.

Optimizing Industrial Products for Performance and Efficiency

In industries such as HVAC, electronics, and pumps, product design directly impacts efficiency, reliability, and energy consumption. Through product development Services and industrial design consulting, CFD Vision helps clients optimize performance through simulation and design validation.

Take HVAC systems, for instance. By simulating airflow and temperature distribution within duct networks, we can identify bottlenecks, optimize fan operation, and reduce energy costs. In electronic cooling, simulations help predict hotspots and guide component placement to enhance thermal management, preventing failures and extending lifespan.

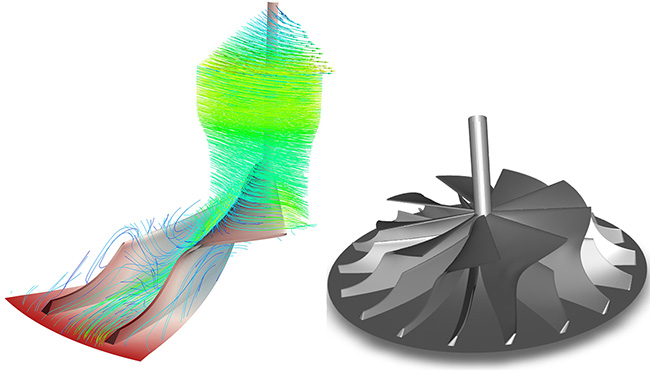

Similarly, in industrial pumps or heat exchangers, engineering simulation allows engineers to optimize impeller designs, reduce cavitation risks, and improve heat transfer efficiency. These improvements directly translate into measurable performance gains, lower maintenance costs, and better overall system reliability.

Virtual Prototyping for Cost-Effective Product Innovation

Virtual prototyping is a cornerstone of modern product innovation consulting. Our engineers use digital twins and CAD modeling to evaluate the performance of mechanical components, consumer products, or energy systems before production.

Whether optimizing cooling channels in an automotive brake system or improving fluid flow in small appliances, CFD simulation services reduce design uncertainty and prevents costly production issues — turning creative ideas into manufacturable products faster.

Strengthening Mechanical Design with Advanced Simulation

Modern industries demand components that can withstand high stresses, fluctuating loads, and complex operating environments. At CFD Vision, our product development consultants use engineering simulation to evaluate structural integrity, fatigue life, and thermal-mechanical interactions in critical components.

For example, in rotating machinery such as turbines, compressors, or pumps, predicting stress distribution and identifying potential failure points ensures safe and reliable operation. In consumer appliances and automotive systems, mechanical analysis helps reduce weight without compromising durability, contributing to product innovation and energy savings.

By integrating CFD simulation with finite element analysis (FEA), we provide a complete picture of how a design behaves under real-world conditions. Our product design consultants help balance performance, weight, and reliability — reducing material waste while ensuring compliance with engineering standards.

Improving Fluid Flow and Heat Transfer in Academic and Industrial Equipment Design

From chemical reactors to pipelines, equipment design directly affects operational efficiency. Our product design consultants helps engineers optimize fluid flow, mixing, and heat transfer to enhance process performance.

For instance, simulating flow in a chemical reactor allows engineers to identify dead zones, improve mixing, and reduce energy consumption. Pipeline simulations can prevent pressure drops, cavitation, and uneven flow distribution, enhancing overall system efficiency. Small-scale machinery, such as pumps and heat exchangers, also benefit from design optimization, improving durability and energy savings.

Real-World Benefits of Partnering with CFD Vision

Collaborating with CFD Vision gives companies access to multi-disciplinary expertise in CFD, product design services, and industrial design consulting. Partnering with us means you can:

- Accelerate product development through faster design iterations

- Reduce costs with virtual prototyping and predictive simulations

- Achieve reliable, data-driven equipment design

- Innovate confidently with scientifically validated predictions

- Enhance performance, safety, and efficiency across all systems

Our approach ensures that engineers and decision-makers have the insights they need to make informed design choices, avoid costly mistakes, and achieve market-ready innovations faster.

Challenge: Are You Maximizing Your Design Potential?

Many companies still rely on partial testing or outdated design methods. How much better could your products perform if every design decision were supported by precise CFD simulation services, CAD modeling, and product development consulting?

Conclusion: Take Your Design to the Next Level

At CFD Vision, our product design consultants transform engineering challenges into optimized solutions. Whether you are improving laboratory facilities, industrial products, or additive manufacturing processes, our engineering simulation services provide the insights and reliability you need.

Contact CFD Vision today for professional product design consulting, CAD services, and simulation-driven product innovation that will accelerate your next breakthrough.

Internal links: